Adelchi And Filanto Look To Africa

Filanto inaugurated a few days ago a shoe manufacturing factory in Bangladesh, a country where the Adelchi Group has been making shoe uppers since 1992. Both companies, which are of similar size and based in the Apulia region of Italy, retain major operations in neighboring Albania (see story elsewhere in ...

REGISTER a free Account today to continue reading this article.

SIGN-IN if you are already a subscriber of Shoe Intelligence.

Subscribe today for just €8,36 a week

Your membership benefits:

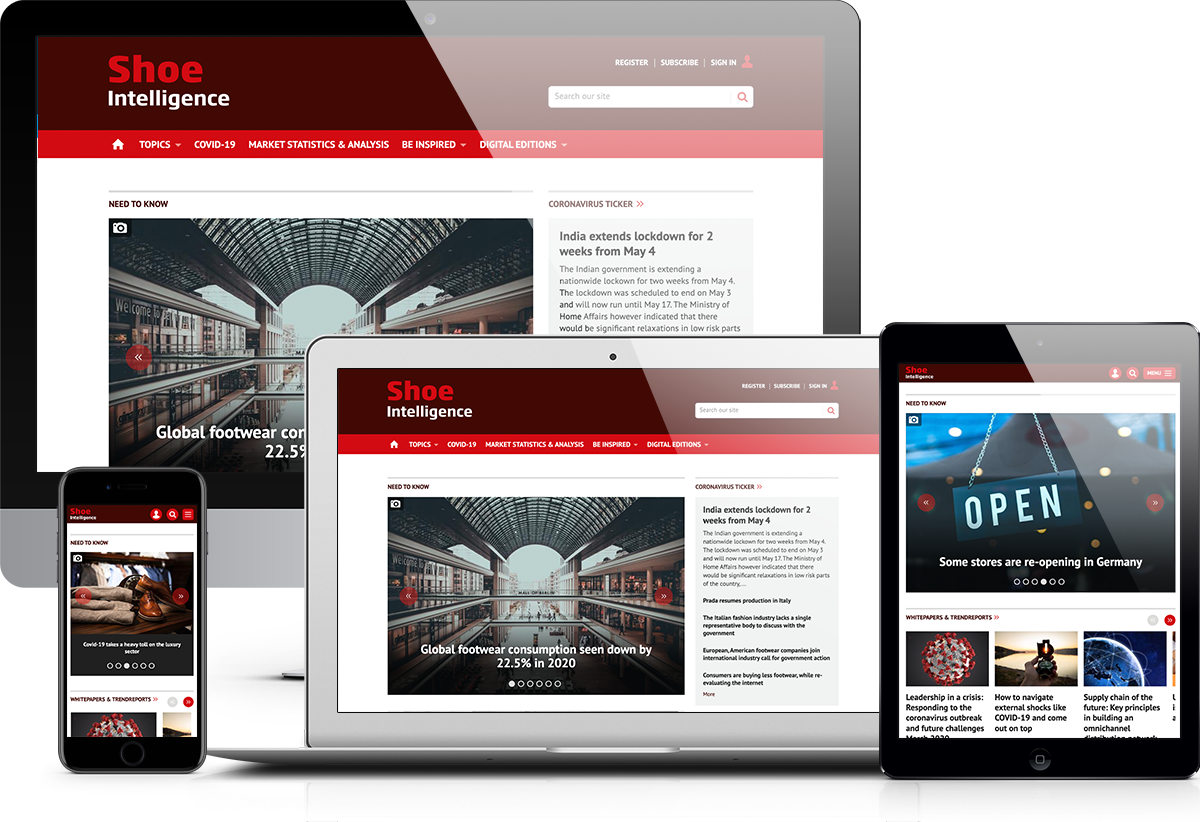

- Unlimited access to shoeintelligence.com - all insight, analysis and statistics 24h/day available online

- Our executive edition of Shoe Intelligence (Digital Edition) - the must-read for all decision-makers in the industry

- Weekly E-mail Briefing from the Chief Editor with the lastest analysis and most important industry developments

- Case studies and best practices on business challenges

- Guest chronicles, interviews, insights from industry experts and leaders that are shaping the future of the industry

- Unlimited access to shoeintelligence.com - all insight, analysis and statistics 24h/day available online

- Powerful search and access to over 16,500 articles and analyses in the archive

- Personal library to save articles and track your key content

If you aren’t ready to subscribe now, choose the 30 day trial for 1€. To continue reading this article REGISTER NOW.