World Footwear helps shoemakers to deal with Brexit

The Portuguese shoe industry association, Apiccaps, has posted a useful guide on the website of World Footwear with practical checklists for shoe exporters and importers on how to deal with the new trade agreement between the U.K. and the European Union. It also organized a few days ago an interesting ...

SIGN-IN if you are already a subscriber of Shoe Intelligence.

Subscribe today

Your membership benefits:

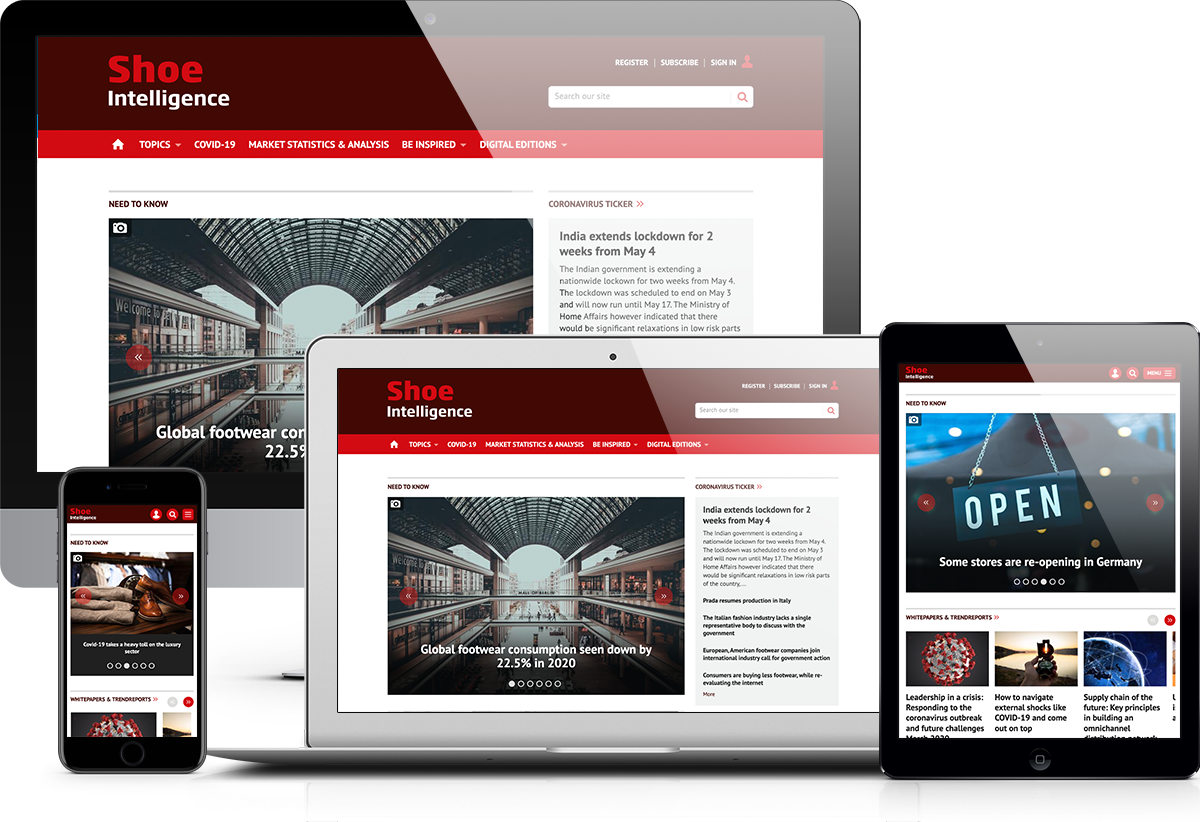

- Unlimited access to shoeintelligence.com - all insight, analysis and statistics 24h/day available online

- Our executive edition of Shoe Intelligence (Digital Edition) - the must-read for all decision-makers in the industry

- Weekly E-mail Briefing from the Chief Editor with the lastest analysis and most important industry developments

- Case studies and best practices on business challenges

- Guest chronicles, interviews, insights from industry experts and leaders that are shaping the future of the industry

- Unlimited access to shoeintelligence.com - all insight, analysis and statistics 24h/day available online

- Powerful search and access to over 16,500 articles and analyses in the archive

- Personal library to save articles and track your key content

- Organisation-wide access across offices, people and devices

To continue reading this article REGISTER NOW.